INDUSTRIAL wastewater can be turned into drinking water without relying on electricity, a three-month water desalination trial at Newport power station has shown.

And with all of the west’s industry, the technology could potentially be used to irrigate municipal parks and ovals.

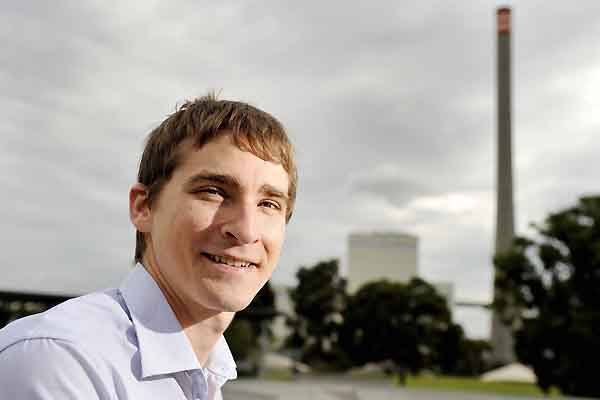

Associate Professor Mike Duke, who lives in Newport and works at Victoria University’s Werribee campus, said the pilot project demonstrated that a desal plant could be powered using an industry’s own waste heat.

Operating at full-scale, a medium-sized industry could desalinate about seven-million litres of water a day – enough to supply fresh water to 25,000 Melburnians.

“There’s this technology around the world that is being developed and being targeted at these hot spots where the industry is discarding its heat,” Associate Professor Duke said.

“We just put our technology in that path and then use it to convert to treated water.

“There are a lot of industries that are keenly watching this technology and we are already in consultation with the mining, manufacturing and dairy industries as well as water utilities to move to larger pilot trials.”

Associate Professor Duke said the membrane distillation technology used 50percent less electricity to desalinate water than traditional techniques, while an updated design used 95percent less.

Local desal plants could also combat the tyranny of distance, he said.

“Water is very expensive to move around. Sometimes the most expensive part of providing treated water is getting it to the place that it’s needed.

“There’s a lot of industries in the western suburbs and something like the technology we’ve been developing helps to improve water self-sufficiency and puts less demand on the drinking-water supply.”